METAL 3D-PRINT

3D-printing of metal components is the most ambitious, expensive and cost intensive discipline of additive manufacturing. Laser-sinstering, laser melting and laser-cusing are the 3D-printing processes for which there is a growing market. Companies such as Airbus are currently looking ahead with their plans to switch the bulk of their manufacturing to metal-3D-printing.

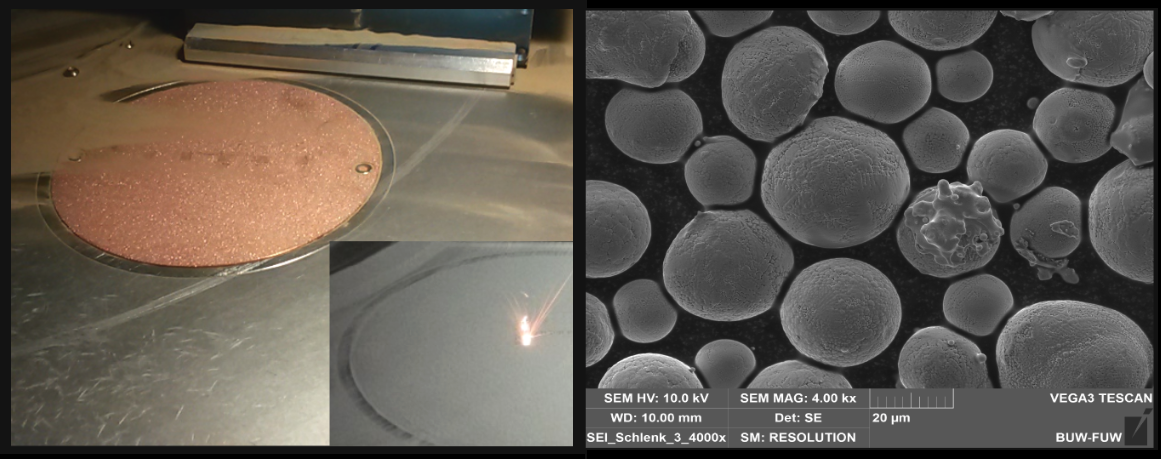

We too in the 3D-printing network Solingen are already investing in 3D-metal-printers. We will shortly report on the activities of our partner Klaus Stöcker Metallbearbeitungconcerning this. Laser-sintering with metal powder is also a focus of research in the university landscape. Our network member, the Bergische Universität Wuppertal is breaking new ground with copper-based metals in this area (see picture above, more).

SERIAL PRODUCTION WITH 3D PRINTERS? NO PROBLEM. AND IT GETS EVEN BETTER…

The Bergische Struktur- und Wirtschaftsgesellschaft (BSW) made a wish shortly before Christmas:

The BSW needed a few hundred copies of a 3D model of Schloss Burg as give-aways for the international trade fair for experiential marketing (BOE) on 10 January in Dortmund.

There was only one solution for such a demand at short notice: 3D printing. The task was to produce the model from clear, transparent plastic. The 3D Network itself has a Form 2 3D printer (manufacturer: 3D Network member Formlabs) which allowed the filigree structure of the object to be printed quickly.

The Form 2 combines industrial quality with a high level of user-friendliness. The device delivers high-resolution prints in a desktop format at a fraction of the price of the stereolithography (SLA) that was used until recently. In stereolithography 3D printing, a light-curing plastic (synthetic resin) is cured by a laser into thin layers.

With the support of our 3D Network member EXCIT3D GmbH, which provided 3D printing-compliant design and post-processing, we started serial production in a very short time. In fact, it was finished punctually with only one Form 2.

But we have only explored a fraction of the possibilities of 3D printing. Instead of producing the same model 300 times, 300 different copies could have been created.The additional cost of this: Zero. Just imagine what 300 different moulds would cost.

We will shortly be showing how we use the 3D model of Schloss Burg as an example for showcasing the possibilities of 3D printing in producing a wide variety of variants.

3D printing is used to produce products when, where and how they are needed. Our 7 theses on the revolution of production by 3D printing show how additive manufacturing turns the previous laws of production upside down.

3D Network & 3D focus, the leading 3D platform in China, agree on cooperation

Last week, 3D network manager Werner Koch and Li Peixue, founder and chairman of the leading 3D printing service provider 3D focus, signed a cooperation agreement in the Chinese city Quingdao.